Across the shapes. From the patent drawings of Salvatore Ferragamo to 3D model

- Michele Calvano

- 7 set 2014

- Tempo di lettura: 6 min

This post is an abstract from an article sent to UID Conference 2014 - "ITALIAN SURVEY & INTERNATIONAL EXPERIENCE". In this international showcase, me and Prof.ssa Elena Ippoliti have decided to speak about a big Designer in Italy and abroad, Salvatore Ferragamo and his art.

Special Thanks to Alex Coppola and Riccardo Bernardi, authors of some drawings.

Survey and industrial product

In surveys applied to industrial production, it is customary to use the term reverse modeling (Gaiani, 2001), derived from the reverse engineering, which is a procedure aimed at the “engineerisation” for the purpose of production.

In the use of the expression reverse modeling still remains the original intention: that of a tension towards the project. One of its definitions is indeed that of reverse process aimed at the understanding of the project, an “approach from which to reconstruct or derive the geometry of an object” (Gaiani, 2001).

Normally the reverse modeling is applied to existing objects - finished or prototypes - from which are derived quantities of points (more or less discrete) of known spatial coordinates. As with any survey, in the reverse modeling it is possible to distinguish between operations aimed at acquisition of data, and those relating to the processing and the subjective choices of the detector (upstream interpretations in the selection of data, or downstream ones in the construction of representations), which are made available to the evaluation of other researchers. This is the basis of its scientific nature, ensuring repeatability (Migliari, 2001).

From these initial considerations, it emerges how the experience described below is still partially incomplete. However, the inestimable value of patent documentation by Salvatore Ferragamo, a cultural deposit made mostly of drawings that can be enhanced by means of design and surveys, has been for us urgency not postponable.

Although to the limits, in our opinion, the proposed experience is still as pertaining to the area of survey, in the case of applications to objects of industrial design, in particular for the so-called free-form objects. Below, we will highlight the main criticalities and describe the steps.

The intention is to offer a hypothesis of procedure, a kind of prototype to be refined, which will be improved in later research by acquiring additional data from other projects, shapes and shoes preserved in the Museo Salvatore Ferragamo (Florence).

This is a hypothesis that we propose as a cognitive strategy of patent drawings to derive the design strategy, which was possible to formulate by working through similarity of “forms”, thanks to digital modeling.

For a prototype of survey

Among the elements of criticality, one first notices the fact that each of the projects of footwear is described, in principle, from a single drawing, albeit within a series of similar models. Then, of course it is not possible state that the geometrically complex shapes were constructed from an exact geometric control (unlike some contemporary architecture). Certainly an “intentional geometry” is traceable in the unique design ambition of Ferragamo that is, to quote his own words, to make “the perfect shoes” (Ferragamo, 2010, p. 11). For this reason, he devoted himself to the study of the foot anatomy, from which, through various experiments of measurement, he found the similarity of “form and structure”. From this “discovery” he derived new principles in the feet measurement system (Ferragamo, 2010, p. 65) and he refashioned the forms. And on this discovery, “not on the drawing, the style, the handcrafted manufacturing” but on comfort, he founded his fortune (Ferragamo, 2010, p. 65).

In order to find the definition of a cognitive strategy, we have taken as a reference the concept of comfort. Then we have decided to proceed in analogy to the process traditionally adopted in the implementation of the prototypes of footwear’s models.

At this point, when the “model” is drawn on paper, the process continues to the preparation of the “foot shape”, a prototype that represents the interpretation of the volume of the foot. This is constructed from the anatomical shape and differs in relation to the client and the model of shoe, as well as the height of the heel. The prototype of the shoe model is then built on the form: for this reason it is coated with paper, obtaining the so-called “shirt”. Finally, the model of the shoe is printed on the shirt, tracing on it the “drawing of style lines.”

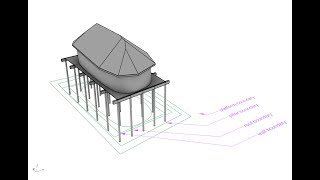

To define the procedure, as in any discovery process, we were concerned about pre-understanding the subject that we were going to rebuild. We distinguished the individual components that typically occur in footwear (fig. 3). These are the upper (upper part of the shoe), the sole (bottom of the shoe) and the insole (shoe insert) and the heel (the upward place under the rear of the shoe in continuity with this).

Taking advantage of the geometry research, each of the components has been recognized and understood as “geometric figure” not further reducible. These are describable as complex surfaces, controllable through the identification of notable characteristic curves (edges or isoparametrics), on which then “unroll” the surface portions. In other words, it was possible, in each of the figures, to identify characters of “reproducibility and mathematical rationality” (Migliari, 2010).

It was then decided to adopt the “foot shape” as standard of measurement, as ergonomic and anthropometric reference model, namely “modulus and modus (...) ideal Platonic shape” (Gaiani, 2004). The tool adopted to carry out the reconstruction of the “model of the project” has been traced in the geometry with which to control simultaneously both the “designed shape” and “the standard shape of the foot”, proceeding iteratively by successive approximations and interpretations. Finally, the accuracy of the experience was placed in the detailed description of the different stages of work, or rather in the description of the procedure.

The experience was possible because the digital space has allowed us to make the drawing of the patent and the foot shape homogeneous and comparable, since converted into numerical models. Each patent drawing has been digitized by deriving a raster image, and a numerical representation, the polygonal mesh of the foot shape, was imported, in turn obtained by laser scanning of a real shape.

Once acquired the two numerical models, the following steps have focused on the derivation of the respective mathematical models, integrating information (discrete data) through successive interpretations and evaluations for the reconstruction of the best mathematical surface.

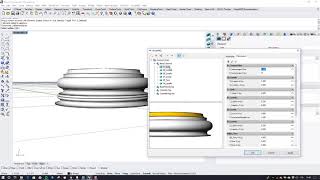

For the foot shape, with the objective to describe it with the minimum number of NURBS portions, the cylinder was assumed as initial primitive form to be deformed. Indeed, on the basis of observations of topological character, the cylinder and the shape are definable as objects homeomorphic between themselves (fig. 4). Ideally, from the “deformation without rips” of the primitive solid, it is possible to derive, in a first approximation, the initial observations to understand how to orient the curves to be projected on the model; the latter would have been used as isoparametric curves of the consecutive mathematical model. In detail, the radial lines (curves of first degree) belonging to the horizontal plane with the centre placed inside the instep (upper arch of foot) have been plotted from the top view. Once the curves on the mesh were projected, the resulting polylines were rebuilt, converting them into splines regulated by an adequate number of control points and with degree equal to three. These constitute the set of isoparametrics that gave shape to the surface along a direction. Then, working on the side view, graphic curves (third degree) were drawn in the vertical plane, supporting the longitudinal course of the mesh model and describing on this, once projected, a group of closed lines that gave shape to the second isoparametric direction. The mesh of curves obtained was sufficient for the reconstruction of the mathematical surface of the foot shape (fig. 5).

To close the foot shape it was necessary integrate it with the surface of the insole; along the direction normal to the horizontal plane, straight lines almost parallel to each other and perpendicular to the longitudinal direction of the shape were projected. The result was again a sequence of polylines limited to the lower edge of the mathematical surface previously obtained. From these lines, operating in a similar way, we obtained the splines able to orient the new mathematical surface; the closed polysurface on which operate was obtained by closing the upper edge of the shape.

Finally, by working on the vertical plane in which the raster image lied, initially the patent drawing was suitably scaled, and then the geometry of the foot shape has been transformed as long as the apparent contour has not been adapted to the main graphic lines that characterize the model of the shoe (fig. 6).

Next step was the reconstruction of the shoe's model, trying to locate also in this case the portions of surface with double curvature in the various elements that compose it (upper, outsole and insole, heel and accessories). Each portion of surface was reconstructed from graphic lines derived from the patent drawing, but plotted in the space favouring the shape of the foot (figs 7-10).

Comments